|

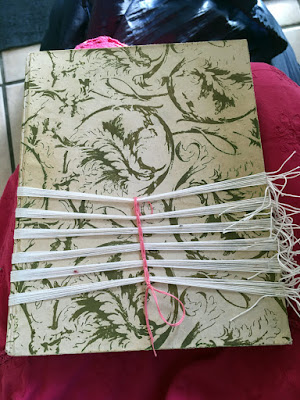

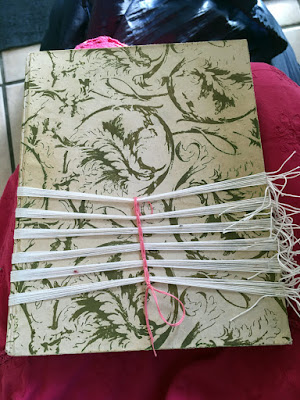

| Beautiful warp on beautiful warping board. 11 feet? 4 yards? Something like that. |

Because I am nothing if not a glutton for punishment (and user of tools in fashions for which they were not intended...see

Exhibit A and

Exhibit B), when K asked for a scarf for Christmas, I decided to weave it on my little rigid heddle loom. In 2x2 twill.

|

| The catalog pages are to cover the sticky glue residue from the velcro I peeled off. |

In case you don't speak loom, rigid heddle looms create two sets of warp threads, half of which stay in the plane of the woven fabric while the other half move above or below that plane. The stationary threads go in slots, and the mobile threads go through holes in the heddle. Over-under-over-under goes the weft thread, and that's all it does, and it does it very well.

For 2x2 twill (or any base-4 twill, but let's stick to this), you need to be able to lift four different sets of threads in sequence. If you have threads 1, 2, 3, and 4, you'll need to pick up threads 1 and 2, 2 and 3, 3 and 4, and 4 and 1 as sets, and repeat that pattern as you weave your cloth. This...is a problem, on a rigid heddle loom, because it can only do two sets of thread.

I

could put every fourth thread through the holes of the heddle, and lift each of the other sets with a stick I inserted by hand. Every row. That sounds kind of like work, though, and I'm allergic to work (yes, yes, it's very sad, incurable, terrible tragedy).

Instead, I've decided to use the heddle as a reed, passing two warp threads through each slot (so they can move freely), and make string heddles for each of the four sets of threads I'll need to lift. Lots more front-end work, but it'll make the actual weaving much simpler.

|

| Weaving is a remarkable process whereby you cut a bunch of string and make a mess, and then you make it even more organized than it was to begin with. |

I got the heddle threaded in about an hour, while baking crackers—so some of that time I wasn't actually touching yarn.

|

| That rug really needs help. A washing. Or a match. |

Winding on was slow, but fairly graceful, and I remembered that inserting sticks every once in a while to keep the threads rolling on evenly is a

non-optional part of weaving, so my tension should be miles better this time than it was for the last scarf. (I didn't blog about that one. It was also for K, and is a lovely handspun-by-someone-else fawn alpaca with white alpaca in a semi-houndstooth pattern. It has...some selvedge issues. He still loves it, though.)

|

| This is the most use that notebook has seen since 2009. |

For twill, I needed to set up string heddles of some kind, and I have not been very good at making continuous heddles a consistent length before, so I decided to bite the bullet and make a few (hundred) individual heddles with leftover crochet cotton. The great advantage, other than being able to tie them around a notebook for definitely-consistent lengths, is that if I make a threading error, I can easily move the heddle where it belongs by unlooping it from the shaft and relocating it. (Keep scrolling, it'll make more sense in three photos.)

|

| I think weavers chain everything they can get their paws on. |

I made sixty heddles for each shaft—two more than I needed, but extras never hurt. I sectioned them in groups of ten as I tied them, and chained each finished bundle to keep them organized until I could put them on the loom.

|

| Yes, I did that on purpose. |

Aren't they charming? I used a different color for each shaft, to make my life easier when I'm trying to sort through three shafts of 58 heddles apiece all draped across the warp.

|

| There's a lot going on here. |

Shaft one went pretty smoothly; I used two stick shuttles to pick up each warp thread that belonged on the shaft, and they served as a backdrop while I looped each heddle around each warp thread for this shaft, and slid them onto a dowel.

|

| Okay, I lied. There's definitely a lot going on here, though. |

Shafts two and three, done the same way, plus very carefully sliding one stick shuttle through the next shed, and then shifting the second one before starting to thread everything. Here's hoping it all goes smoothly (okay, spoiler alert, this part happened well before Christmas, and it...did not. There will be updates).

Comments

Post a Comment